Vinyl Flooring Manufacturer

We Provide The Best Vinyl Flooring For Your Business and Projects!

Years Of Experiences

About SUNTONE

We Have 10+ Years of Experience in Vinyl Flooring Manufacturing

We are passionate about providing our customers with high-quality vinyl flooring that is built to last. We use the latest technology and equipment to create various colors and styles to meet customers’ needs.

- Best Quality Standards

- 100% Satisfaction Guarantee

- Quality Control System

- Commitment to Customers

- Highly Professional Team

- Best Materials

Rick Choi

Marketing Director

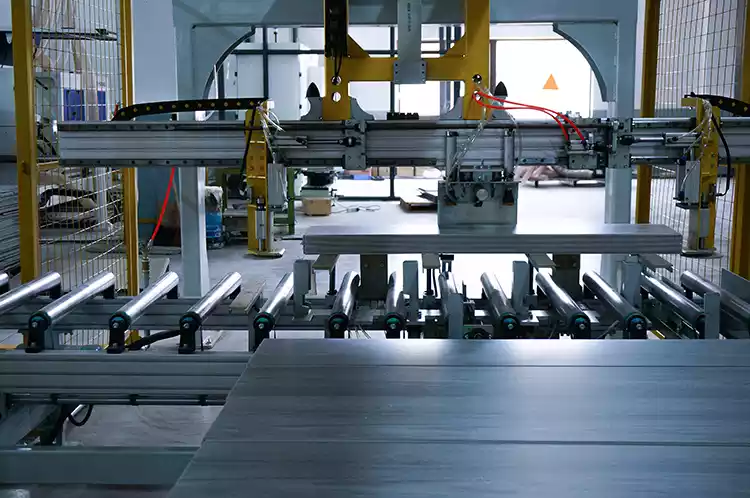

Factory Overview

Visit Our Factory

Our factory has advanced SPC/LVT production lines and an advanced laboratory to ensure the quality of the vinyl flooring.

Testing Lab

Product quality has always been our top priority. All of our products go through rigorous quality control processes to meet the highest standards.

Why Choose Us

We Provide The Best Vinyl Flooring For Your Business and Projects

We have become a designated OEM supplier for many famous brands abroad, exporting to over 20 countries globally. You can trust that SUNTONE will be a valuable partner to your business and projects.

Our Vision

Dedicated, motivated, and committed to excellence. To be the leading provider of vinyl flooring in the world.

Our Mission

We're constantly striving to meet that goal to provide our customers with the best possible vinyl flooring products.

Work With Us

Our Working Proccess

SUNTONE has built a reputation in the vinyl flooring industry through its consistent quality and competitive price in the international market.

01

OEM Communication

Choose the suitable wear layer and rigid-core thickness, and select the colorful texture; underlayment also is optional.

Sampling

FREE samples are ready for your evaluation upon request. Choose the stock samples or customization.

02

Contract & Payment

Generally, our payment term is 30%T/T in advance, and 70% balance before shipping; we also accept L/C at sight.

03

04

Bulk Production

The bulk production started according to the confirmed samples. Our advanced production lines guarantee quality and lead time.

QC & Packaging

Before shipment, all our floors are inspected for quality and packed for shipment only after they are qualified.

05

Shipping

We work closely with several shipping companies to ensure that the goods reach you in the fastest possible time.

06

Need Flooring Advice? Ask Our Experts For Free, Glad To Help You

We offer various vinyl flooring options, colors, and textures. Customization is also available. Whatever your style or budget, we are sure to have the perfect vinyl flooring for you.

Our Team

Meet With Our Expert Team

We have served many famous brands with excellent customer service, high-quality floors, and fast turnaround times.

Sales Team

SUNTONE FLOORING