SPC Flooring Manufacturer

As an SPC flooring manufacturer, we offer SPC products in various styles and colors so that you can find the perfect style for your business or projects.

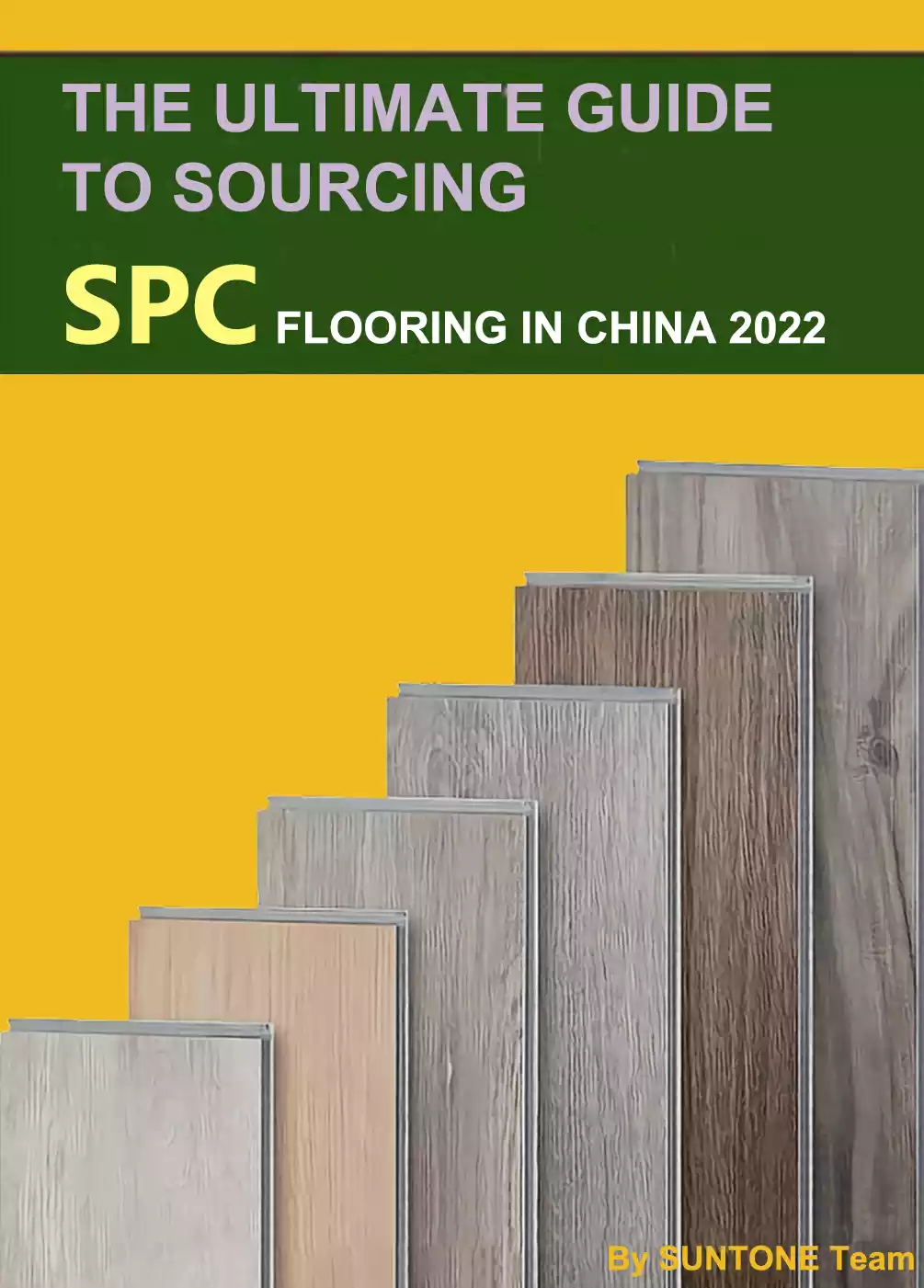

SPC Flooring Wholesale Guide

Ultimate Guide

Want to import SPC flooring for your projects or wholesale in your market? This ultimate guide would help you with everything about the product and import information.

About SPC

What Is SPC Flooring

SPC flooring is a type of vinyl floor made with stone polymer composite materials. These materials are combined to create a durable product resistant to moisture and wear.

SPC flooring is also easy to install and maintain, making it a popular choice for home and commercial use.

No matter where it’s installed, SPC flooring is sure to provide a long-lasting, attractive finish.

Our SPC flooring uses 100% virgin material to ensure maximum durability and long-lasting beauty and fulfills heavy-duty performance requirements.

So why wait? Contact us for FREE samples today and see why it’s so popular.

About Structure

SPC Flooring Structure

1. UV Coating

It enhances the clarity of the decoration film and resists fading.

2. Wear Layer

Scratch Resistance. For durability over 20 years. Widely used for residential areas, shopping malls, etc.

3. Decorative Film

Modern design based on the most popular models on the market.

4. SPC Rigid Core

It is made of superfine stone plastic composite material.

5. Underlayment (Optional)

It uses IXPE or EVA, can enhance the floor’s grip, fits existing surfaces, and reduces noise.

6. Click-Lock Installation System

Easy installation and making the floor sturdy and waterproof.

Parameter

SPC Flooring Technical Data

SPC flooring is waterproof, slip-resistant, and fire-resistant, making it a safe option for many different settings.

| Characteristics | Test | SPC |

| Classification | EN685 | 21~44 |

| Dimensions | ISO24341 | 220 * 1220 mm 610 * 305 mm (for tile) |

| Straightness / Squareness | ISO24342 | ≤0.25mm |

| Thickness | ISO24346 | 5mm ± 0.15mm |

| Wear Layer Thickness | ISO24340 | 0.55mm (+13%/ -10% ) |

| Weight | EN430 | 9.3kg/㎡ |

| Abrasion Resistance | EN660:part-1 | Group T:≤0.08mm |

| Residual Indentation | ISO24343-1 | ≤0.10mm |

| Chemical Resistance | EN438 | Grade 5 |

| Fire Resistance | EN13501 / ISO9239-1 | Class Bfl S1(B1) |

| Dimensional Stability | ISO23999 | ≤0.12% |

| Color Fastness | ISO 105-B02:1994 | ≥Grade 6 |

| Slip Resistance | AS4586 / DIN 51130 | R10 |

| Formaldehyde Emission | EN717-1 | E1 |

| Curving | ISO23999 | ≤1.2mm |

| Peel Resistance | ISO 24345 | ≥75N/5cm |

| Click Force | ISO 24334 | ≥120N/5cm |

| Anti-scratchs | —— | ≥2500g |

| Acoustic Performance | EN ISO 717-2 | △Lw=10 dB |

| Cigarette burn resistance | EN438-2 | Class 3 |

| Castor Chair | ISO4918 | After 25 000 cycles, no delamination shall occur. |

Our Patterns

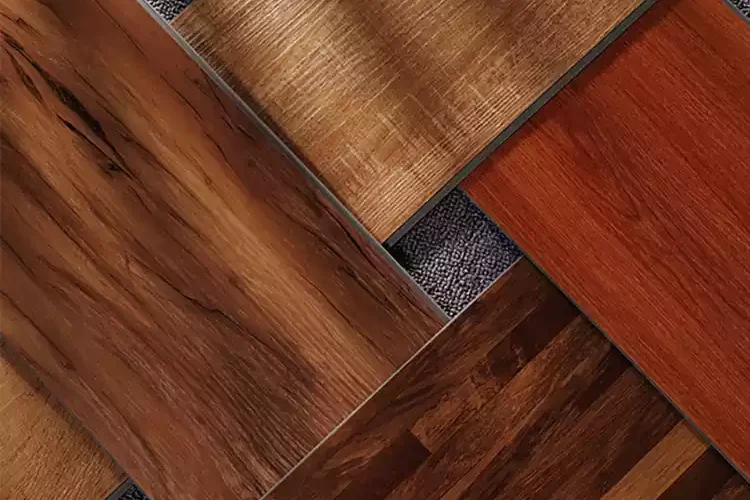

Choose The Suitable Patterns For Your Floor

SPC flooring comes in various colors and patterns, including wooden/marble/carpet patterns, so it is easy to find a style that fits your business and projects.

Wooden Pattern

Marble Pattern

Carpet Pattern

Feartures & Benefits

SPC Flooring Advantages

SPC vinyl flooring is easy to install, durable, and low maintenance. It’s an excellent choice for high-traffic areas or rooms.

100% Waterproof

The SPC flooring is mainly made of superfine stone powder. It has no affinity with water, so it is naturally waterproof.

Fire Resistant

The SPC flooring’s fire-resistant index can reach the B1 level; the fire-resistance performance is excellent.

Scratch resistant

The super wear-resistant layer fully ensures the excellent wear resistance of the SPC flooring—very durable.

Easy Installtion

SPC flooring installation uses high-tech click-lock technology without cement mortar and glue.

Easy Clean & Maintain

Cleaning SPC flooring is convenient; when it is dirty with a mop that can be wiped, you only need regular maintenance.

ECO-Friendly

The primary raw material of the SPC flooring is superfine stone polymer composite material, without harmful materials.

How To Install

Installation Guide

SPC flooring uses click-lock installation technology, meaning the planks click together simply like a puzzle.

UNICLIC

VALINGE

I4F

Years Of Experiences

Why Choose Us

We Have 10+ Years of Experience in Vinyl Flooring Manufacturing

We are passionate about providing our customers with high-quality vinyl flooring that is built to last. We use the latest technology and equipment to create various colors and styles to meet customers’ needs.

- Best Quality Standards

- 100% Satisfaction Guarantee

- Quality Control System

- Commitment to Customers

- Highly Professional Team

- Best Materials

Rick Choi

Marketing Director

Our Certifications

SUNTONE vinyl floor meets all the necessary quality and safety standards.

Production Process

How Is SPC Flooring Made

- Mixed Raw Materials

- Extruded Floor Forms

- UV coating

- Cutting Into Floor Shapes

- Floor Slotting

- Sorting and packaging

We have become a designated OEM supplier for many famous brands abroad, exporting to over 20 countries globally. You can trust that SUNTONE will be a valuable partner to your business and projects.

Estimate Price

Affordable Pricing Plans

You can get the SPC flooring wholesale price directly from our factory, no mid-man, starting at around $5.8 per square meter.

- Wear Layer Thickness

- Plank Thickness

- Underlayment

- Surface Treatment

- Click-Lock Patent

Work With Us

Our Working Proccess

SUNTONE has built a reputation in the vinyl flooring industry through its consistent quality and competitive price in the international market.

01

OEM Communication

Choose the suitable wear layer and rigid-core thickness, and select the colorful texture; underlayment also is optional.

Sampling

FREE samples are ready for your evaluation upon request. Choose the stock samples or customization.

02

Contract & Payment

Generally, our payment term is 30%T/T in advance, and 70% balance before shipping; we also accept L/C at sight.

03

04

Bulk Production

The bulk production started according to the confirmed samples. Our advanced production lines guarantee quality and lead time.

QC & Packaging

Before shipment, all our floors are inspected for quality and packed for shipment only after they are qualified.

05

Shipping

We work closely with several shipping companies to ensure that the goods reach you in the fastest possible time.

06

Testimonials

What Clients Say

Purchase Director

We have worked with SUNTONE since 2015. As our requirements have changed over time, they are patient and professional to solve all the problems. I was pleased to work with them, and SUNTONE has always kept in step with its innovation and product development.

CEO

Love the SUNTONE vinyl flooring… fast delivery, high quality easy to install and maintain. The grain and coloring are so natural. It looks like wood flooring but is very durable and waterproof, which is important in both the kitchen and bathroom. I plan to place the repeat order for our other projects!!

Contractor

FAQ

Popular Question

Please get in touch with our specialist if you can’t find the answers. We’re happy to help!

Yes, our free samples are ready for your evaluation upon request.

Yes, we are professional doing vinyl flooring OEM/ODM orders for over 10 years, just send your requirements, you would get the latest technical support.

It usually takes 30 working days. It varies according to the material and quantity requirements.

Once we make a deal, we will update you on every essential step during production and then send you massive and explicit pictures to give you a vivid understanding.

300 square meters each pattern for standard products.

All our flooring can meet international standards, under 100% inspected before each shipment.

In general, the packing will be in cartons and use pallets. Special packing is available according to customers’ requirements.

Our principle is that QUALITY is first, and a free sample is available for your evaluation. The QC team strictly controls each step, and international certifications for your reference.

It was a very enjoyable experience work with SUNTONE company. To get good product price make us competitive in market. The SUNTONE people have high responsebility for quality assurances. What really turned me over was the SUNTONE’s ability to understand how everything works.