PREPARATION

We recommend placing a single order for all floors required for a commercial flooring project.

Contact us to customize your SPC flooring today!

We recommend a professional flooring installer carries out the installation.

STORAGE AND HANDLING:

Always store SPC flooring on a flat surface to avoid distorting the product. Never put it upright, near heating appliances, or in places with extreme temperature changes!

The best way is for you need to acclimate your new SPC flooring by letting them sit at room temperature 55° – 85°F (13° – 30°C) for 48 hours before installation; and maintain the temperature until installation is complete.

The maximum installation size of Three Season Room can be 40′ x40′ (12.2m X 12.2m), with a 1/2″ (13mm) minimum expansion on all perimeter walls or vertical objects before installation.

Subfloors must be clean, flat, and dry when installing the SPC flooring. Before proceeding with your project, the quality, preparation, and surface conditions must be correct for successful installation or correction!

WARNING! DO NOT MECHANICALLY CHIP OR PULVERIZE EXISTING RESILIENT FLOORING, BACKING, LINING FELT, ASPHALTIC “CUTBACK” ADHESIVES, OR OTHER ADHESIVES.

Previously installed resilient floor covering products and the asphaltic or cut-back adhesive used to install them may contain asbestos or crystalline silica.

The products in this carton DO NOT contain asbestos or crystalline silica. Avoid creating dust.

Inhalation of asbestos or crystalline dust is cancer and respiratory tract hazard. Smoking by individuals exposed to asbestos fibers significantly increases the risk of severe bodily harm.

It would be best if you presumed it contains asbestos unless it is positively sure that the product is a non-asbestos-containing material. Regulations may require that the material be tested to determine asbestos content and may govern the removal and disposal of material.

See the current edition of the Resilient Floor Covering Institute (RFCI) publication “Recommended Work Practices for Removal of Resilient Floor Coverings” for detailed information and instructions on removing all resilient structures.

WOOD SUBFLOOR TREATMENT BEFORE SPC FLOORING INSTALLATION

- Remove any existing floor covering.

- Replace any water-damaged, swollen, or delaminated subflooring.

- Make sure the subfloor is level, and nail down any loose boards.

- Repair the wooden subfloor as needed or install 1/4″ APA underlayment grade panels or leveling compound if required.

- Fasten the underlayment panels following the manufacturer’s recommendation.

- Cover the OSB or particleboard subfloors with a 6-mil poly moisture vapor barrier or 1/4″ APA underlayment grade panels to enable the floating installation to move as designed if needed

- The crawl space under the wood subfloor must be well-ventilated with vents. There should be 1.5 square feet of ventilation for every 100 square feet of crawl space.

- Cover all the exposed soil in the crawl space with a 6-mil vapor barrier to stop moisture from getting in.

- The moisture content of the wood subfloor must not exceed 12% using a pin-type meter.

NOTE: Do not install over wood attached to the concrete. Instead, remove the wood and follow the concrete subfloor instructions.

- Measure the subfloor for flatness. Level any unevenness greater than 3/16″ in a 10′ radius (5mm in 3m) using a Portland-based leveling compound. Level joints more than 1/8″ (3mm) deep and 1/4″ (6mm) in width with a Portland-based patching compound.

- You need to measure the flatness of the subfloor. If it is uneven by more than 3/16″ in a 10′ radius (5mm in 3m), you need to use a Portland-based leveling compound to even it out. level any joints that are more than 1/8″ (3mm) deep or 1/4″ (6mm) wide with a Portland-based patching compound.

CONCRETE SUBFLOOR TREATMENT BEFORE SPC FLOORING INSTALLATION

- The concrete subfloor must be less than 80% relative humidity (ASTM F 2170) or less than 5 lbs. moisture vapor emission rate (ASTM F1869). Always measure and keep track of the moisture content results.

- A 6-mil poly moisture vapor barrier is required to protect from substrate moisture over concrete substrates.

- Measure the subfloor for flatness. If any uneven areas are greater than 3/16″ in a 10′ radius (5mm in 3m), use a Portland-based leveling compound to even it out. Level joints more than 1/8″ (3mm) deep and 1/4″ (6mm) in width with Portland-based patching compound.

- Embed the radiant floor heating systems (either hydronic or electric) in the cement subfloor before installing the SPC flooring. The radiant heat system should be turned on two weeks before installation to eliminate excess moisture in the subfloor.

- After installing the SPC flooring, turn the system to its lowest setting. Reach the desired temperature by increasing the temperature by 5°F (3°C) every 24 hours – but do not let it go above 85°F (30°C). The floor surface temperature should never exceed 85°F (30°C), or it may damage the flooring.

- To have the most efficient heating possible, you must use an in-floor temperature sensor and a separate thermostat. Using an outdoor temperature sensor to adjust the water temperature according to how much heat is lost would be best. Create separate rooms with and without radiant floor heating or rooms with different temperature controllers. Do this using a transition profile and following the manufacturer’s installation guidelines. Also, make sure that there is a 1/4-inch (6 mm) expansion gap [5/8 inch (16mm) for areas that will be exposed to temperatures greater than 85°F (30°C)], so the floors can expand and contract.

- Make sure that the subfloor is dry and clean. Remove all debris, sweep, vacuum, and repair surface imperfections and cracks. We recommend removing the existing base trim and installing new moldings after installing SPC flooring.

SPC FLOORING INSTALLATION TOOLS

Utility knife, Tape measure, Safety Glasses, Spacers, Tapping Block, Circular Saw, Gloves, and Pencil. In addition to the standard tools, we recommend having a pull bar and a carpenter’s square available.

If you use any accessories other than the recommended accessories, it may damage your SPC flooring. If this happens, the warranty provided will be void.

Inspect all of the planks before and during installation. If there are any unacceptable planks, get rid of them. You can also use them as cut pieces to start or finish rows after removing the defective part of the plank.

HOW TO INSTALL SPC FLOORING – GENERAL

When installing the planks, mix them up using different cartons, which will help avoid having too many lights or dark panels next to each other.

To get the best results, fit the panels going in the direction of the longest wall and parallel to the light source in the room. Install plank flooring randomly with at least a 12-inch (30 cm) stagger.

Before installing flooring planks or tiles, measure the room. Ensure that the last row of panels is at least 3 inches (8 cm) wide when finishing the installation. We recommend snapping a chalk line to ensure a perfectly straightforward installation.

SPC flooring has been designed for floating installations in indoor areas, including enclosed three-season rooms protected from the elements and ambient temperatures between 0 and 140°F (-17 and 40°C).

You can’t install the SPC products with a pad attached to a separate underlayment.

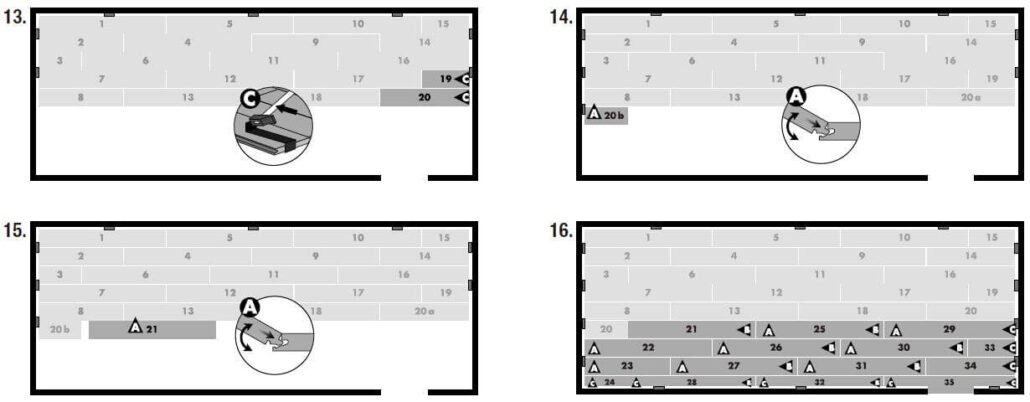

HOW TO INSTALL SPC FLOORING BY UNICLIC SYSTEM

There are two ways to install SUNTONE SPC flooring with a Uniclic locking system:

Method A:

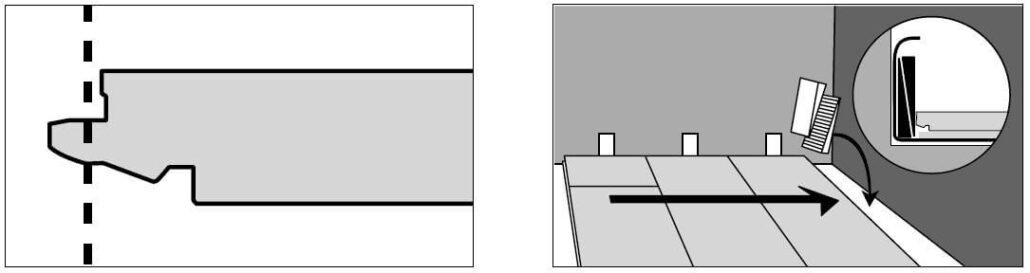

Position the panel to be installed at an angle of 20 to 30° to the installed panel. Move the panel gently up and down and exert forward pressure simultaneously. The panels will automatically click into place. You can either insert the tongue into the groove or the groove onto the tongue. The tongue-in-groove method is more common, and it is easier.

See the diagram below.

Method B:

With Uniclic, you can join the panels without lifting them. For this method, you must use the particular Uniclic tapping block. The planks should not be merged with a single tap. To avoid damaging the panels, you must tap them together gradually.

See the diagram below.

FLOORING MATERIAL INSTALLATION

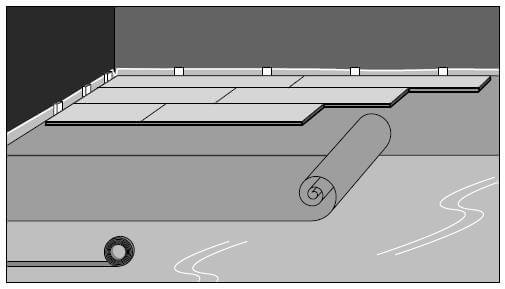

First, install the underlayment. If it is already mounted on panels, You can choose to install the moisture-proof 150μ screen film or not. See the diagram below.

Start by placing a full-length plank against the wall. Next, cut off the tongue on the plank’s long and short sides. Make sure that you leave an expansion space of 1/4 inch (6 mm) [5/8 inch (16mm) for areas that will be exposed to temperatures greater than 85°F (30°C)] between the plank and the wall, using spacers if needed. See the diagrams below for more information.

The diagrams show you how to click or tap the Uniclic panels together. It would be best to angle them up and down or tap them together flat, following the diagrams exactly.

If installing the Uniclic planks with the tapping block (e.g., against the wall) is difficult, you can tap them together using a crowbar and a hammer. See diagrams.

You need to leave a space of 1/4 inch (6 mm) [5/8 inch (16mm) for areas that will be exposed to temperatures greater than 85°F (30°C)] all around the room and on top of any vertical objects. This same space should be left when you use transition moldings.

FINISHING

BASE MOLDING:

- Look at the final surface of the installed floor. Remove all spacers.

- Install base molding to the wall.

- Never attach the base to the floor itself.

- In places where moldings or bases cannot be installed, seal (do not fill) the expansion space with silicone.

UNDER DOORFRAMES:

We recommend undercutting the door jamb when the new flooring meets a threshold or a doorway. Turn a plank upside down and place it on the floor up to the door frame to secure the right cut. Then place a handsaw flat against the plank and cut through the frame. Remove the cut-out piece and vacuum away the debris. You can now secure the plank on the long side of the door jamb. Use an installation tool pull bar to securely join the long and short joints.

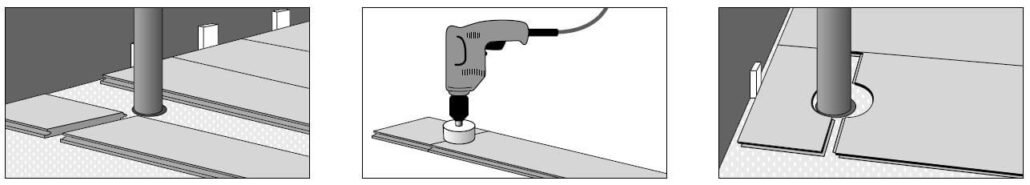

PIPES:

In rows with a pipe, ensure the pipe falls precisely in line with the short side of two planks. Select a drill bit with the same diameter as the pipe plus 1/2 inch (13 mm). Click the planks together on the short side and drill a hole centered on the joint between the two planks. Then install the planks.

For a double pipe, drill a hole equivalent to the diameter of the pipe plus 1/2 inch (13 mm) at each of the marked points. If located on the plank’s long side, make a 45° cut from each hole to the plank’s edge.

Apply sealer along the cut edges of the piece you cut out and seal the piece in place. Be sure no sealer comes between the cut-out piece and the subfloor.

VIEW MORE INSTALLATION OPTIONS

In addition to the Uniclic click system, there are other popular click systems such as Valinge and I4F. Contact us for all installation instructions.

The SPC flooring installation process is simple and straightforward. With the right tools and materials, you can easily install SPC flooring. Follow the steps outlined in this guide, and your new flooring will be installed.

If you encounter problems during the installation process that cannot be solved, contact us, and we will provide you with comprehensive guidance.