As an importer, you are likely well aware of the importance of quality control in your SPC flooring manufacturing process. Quality control measures ensure that the product meets all necessary standards and regulations and help maintain your business’s reputation and trustworthiness. However, while many manufacturers recognize the benefits of implementing robust quality checks throughout their production cycles, understanding how to implement such procedures properly can often be challenging. This blog post will cover why quality control is important in SPC flooring production and how it can form part of any successful supply chain management strategy.

Overview of the SPC Flooring Manufacturing Process

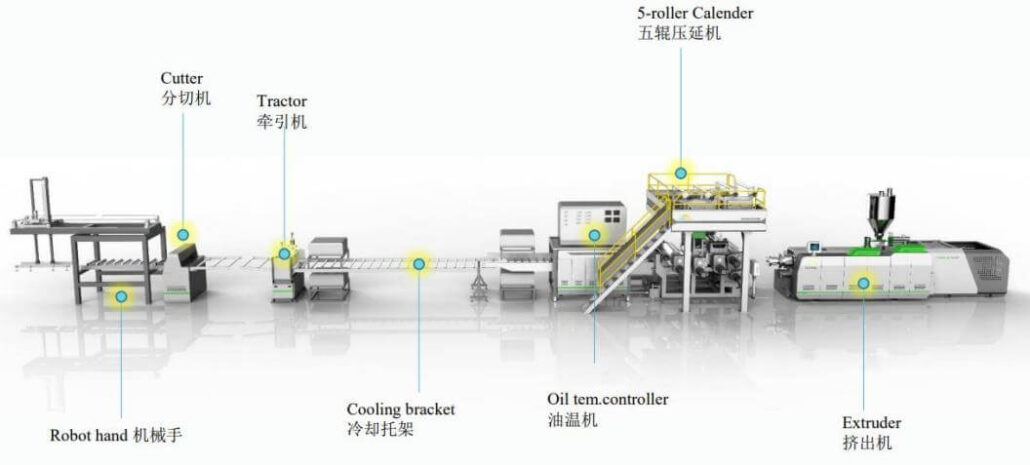

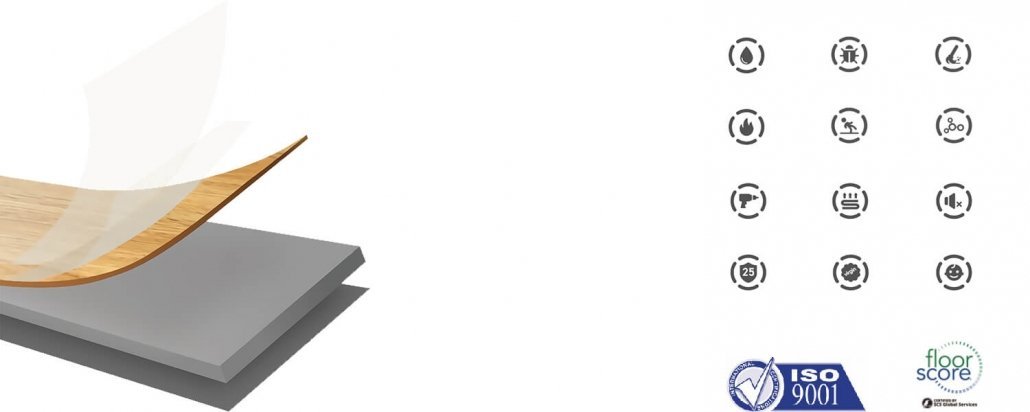

SPC flooring, short for stone plastic composite flooring, has become popular among homeowners and business owners. The flooring comprises several layers, including a wear layer, a décor film layer, and an SPC core layer. The manufacturing process of SPC flooring involves several steps, including mixing and heating the raw materials, extruding the core layer, printing and laminating the décor film layer, and adding the wear layer. The flooring gains durability, water resistance, and a unique appearance. SPC flooring offers a great alternative to traditional hardwood flooring and is easy to install and maintain. With a wide range of designs and colors, SPC flooring can transform any space into a stylish and durable surface.

Benefits of Quality Control in the SPC Flooring Manufacturing Process

Quality control is crucial to any manufacturing process, and SPC flooring manufacturing is no exception. Manufacturers can ensure their products meet the highest safety and performance standards by implementing rigorous quality control measures. The benefits of quality control in the SPC flooring manufacturing process are numerous. It helps reduce waste, increase efficiency, and produce a more consistent and uniform product. By detecting and correcting defects early on in the manufacturing process, manufacturers can save time and money while also improving the overall quality of their products. Ultimately, investing in quality control is a smart business decision that can pay off through increased customer satisfaction and long-term success.

Key Quality Control Points to Consider in SPC Flooring Manufacturing

In the world of flooring manufacturing, quality control is a top priority. Regarding SPC flooring, certain key quality control points must be carefully considered throughout manufacturing. These include material selection, production equipment and processes, and rigorous testing procedures. By focusing on these vital quality control points, manufacturers can ensure that their SPC flooring products meet the highest durability, stability, and performance standards. Whether you’re a flooring manufacturer or a consumer looking to invest in high-quality SPC flooring, understanding these key quality control points is essential for ensuring your satisfaction and long-term success.

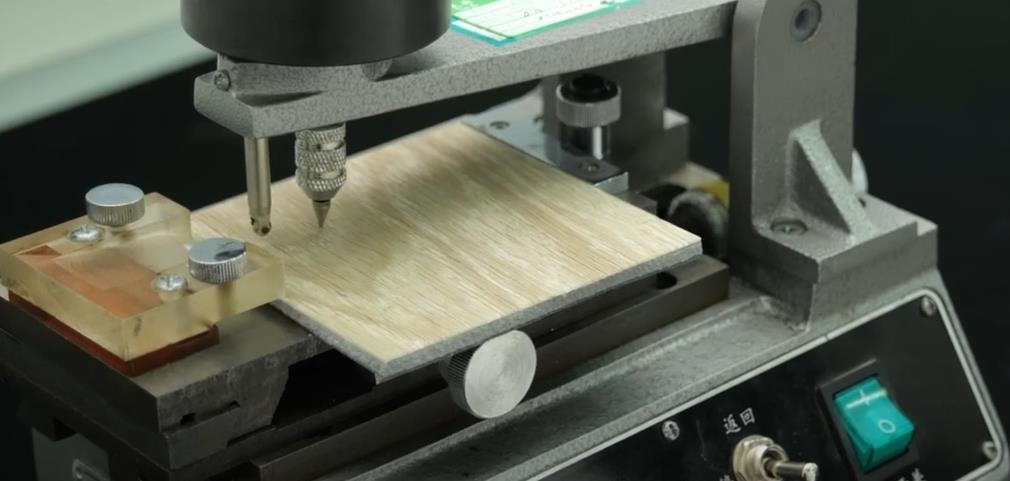

Examples of Quality Control Techniques Used in SPC Flooring Manufacturing

Quality control is key to ensuring a successful product when manufacturing SPC flooring. One important technique used in quality control is Statistical Process Control (SPC). Using statistical tools, SPC helps manufacturers identify and eliminate any variations in their manufacturing processes that could lead to defects in the final product. Another technique used is the Six Sigma methodology, which uses data-driven analysis to improve quality by minimizing defects and variations in the production process. By utilizing these quality control techniques, SPC flooring manufacturers can maintain consistency in their products and deliver high-quality flooring materials to their customers.

How Technology Can Help with Quality Control in the SPC Flooring Manufacturing Process

In the world of manufacturing, quality control is key. It can be the difference between a product that meets customer expectations and one that falls short. Manufacturers always look for ways to improve their quality control processes. One avenue gaining popularity is using technology, particularly in producing SPC flooring. With technological advancements, manufacturers can now use automated systems to monitor every step of the manufacturing process, from material selection to finished product inspection. This not only saves time but also reduces the risk of human error. Plus, with the ability to collect and analyze data in real time, manufacturers can better identify areas for improvement and make more informed decisions moving forward. By leveraging technology, the SPC flooring industry can improve its quality control processes and deliver products that meet and exceed customer expectations.

What Are the Benefits of Implementing a Quality Control System for the SPC Flooring Manufacturer

Implementing a quality control system is crucial for any manufacturing company, especially those in the flooring industry. This is particularly true for SPC flooring manufacturers, who must ensure their products meet rigorous industry standards. A quality control system can help these manufacturers ensure that every aspect of their product – from raw materials to finished goods – is up to par. By implementing a comprehensive system, they can optimize processes, decrease waste, minimize errors, improve customer satisfaction, and reduce costs. In turn, this can lead to increased profits and a better reputation. Ultimately, investing in a quality control system can set SPC flooring manufacturers apart from their competition and help them deliver high-quality, reliable products to their customer base.

In conclusion, SPC flooring manufacturers can benefit greatly from paying attention to quality control during manufacturing. Understanding key quality control points, implementing machine monitoring techniques, and improving documentation will only help ensure high production standards are met and product relies on are kept to a minimum. Using technology in quality control can also be advantageous to an SPC flooring manufacturer as it can provide more accurate data and faster processing, resulting in improved customer satisfaction. Taking all of these elements into account allows the SPC flooring manufacturer to be competitive, strengthen their reputation, and add value to their products.

SUNTONE is a vinyl flooring manufacturer specializing in providing high-quality vinyl flooring to businesses and projects worldwide. Our factory has advanced SPC/LVT production lines and an advanced laboratory to ensure the quality of our products. We are committed to providing the best materials and have become a designated OEM supplier for many famous brands abroad, exporting worldwide!